Category

Laser Welding Fabrication Service for Galvanized Aluminum Sheet Metal Manufacturing

Package Size 100.00cm * 70.00cm * 20.00cm Package Gross Weight 10.000kg Laser welding fabrication service for galvanized

Basic Info.

| Model NO. | YS-2000424 |

| Machining Method | CNC Machining |

| Material | SPCC |

| Advantage | Experience Since 1996 |

| Usage | Electronic Instrument Part |

| Transport Package | Plastic Bag + Polyfoam + Standard Carton |

| Specification | 500*500*10 MM |

| Trademark | Custom logo |

| Origin | China(Mainland) Guangdong |

| HS Code | 8529909090 |

| Production Capacity | 1000 Pieces / Month |

Packaging & Delivery

Package Size 100.00cm * 70.00cm * 20.00cm Package Gross Weight 10.000kgProduct Description

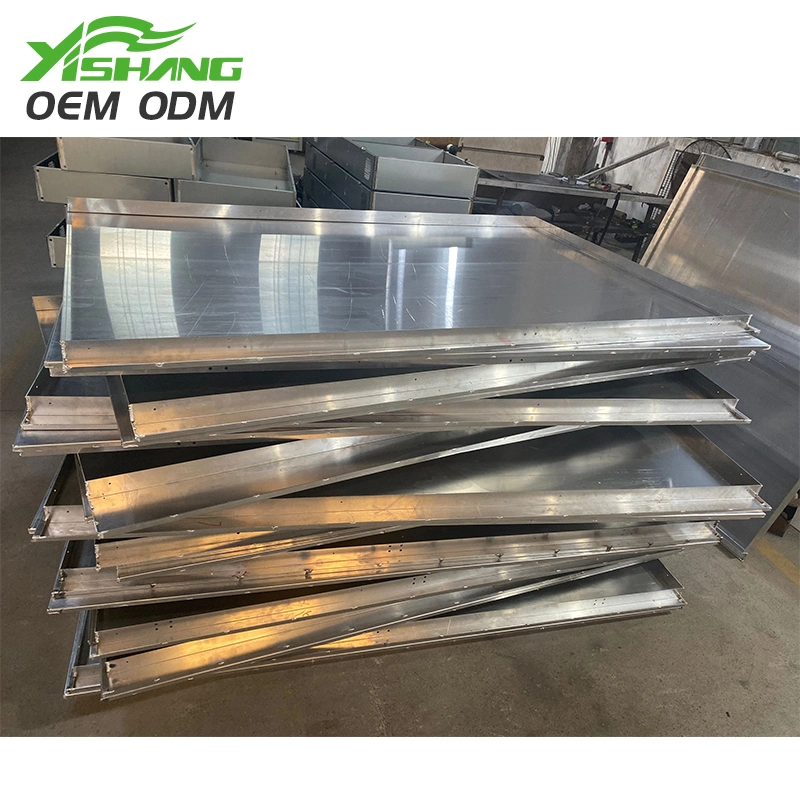

Laser welding fabrication service for galvanized aluminum sheet metal manufacturing

For sheet metal manufacturing, why choose Yishang?1. Sheet metal parts, we can offer free 3D drawings and quotations within 24 hours.2. Large-scale enclosures, the production time of the first sample for mass production is only 2 days.3. Sheet metal samples and small batch production can be delivered within 5 days.4. The finished products are 100% exempt from inspection before shipment, and the quality is guaranteed.

| Technology | CNC Bending, Welding |

| Material | Aluminum sheet |

| Size | Custom according to customer requirements |

| Color | Black, grey, white, etc. Or custom color in Pantone. |

| Surface Treatment | Iron and galvanized steel: powder-coated or painted. Stainless steel: brushed, polished, sandblasted, electroplated, etc. |

| Production Time | Sample: 2- 3 days. Batch order: 10 - 12 days. |

| Services | Professional in customizing all kinds of metal enclosures. |

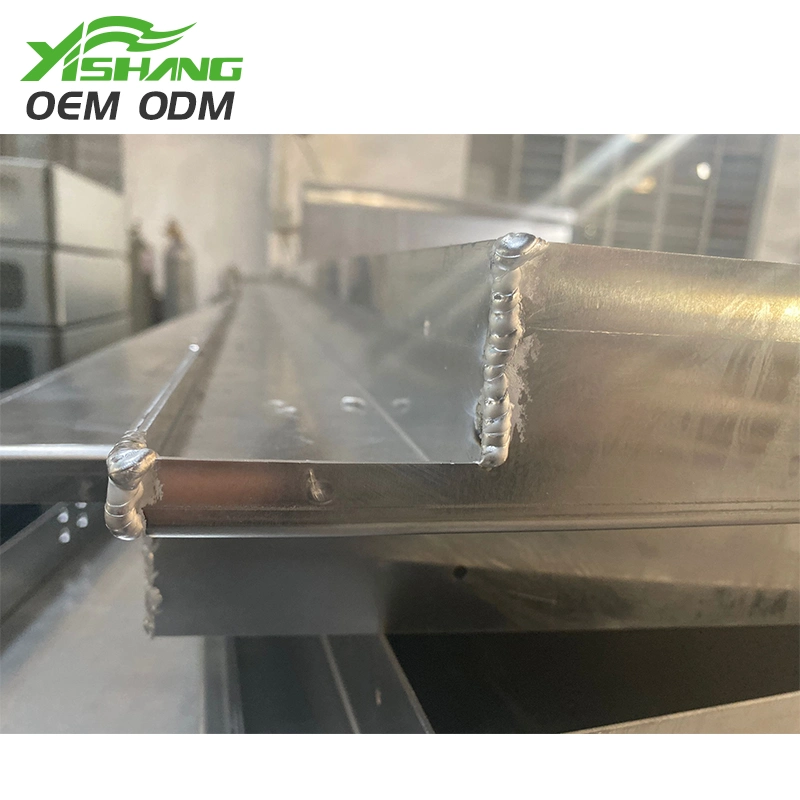

| After bending, the corners are welded together. |

|

| Quality standards for wire drawing:1. The melting degree reaches 100% (steel current 35-50V, iron current 40-50V)2. Before and after welding, straight and thin from left to right3. No holes, no gaps, no shadows, no deformation, no bubbles |

|

| Quality inspection standards for CNC bending: 1. Angle (within + -50c) 2. Length and width (within + -20c) 3. No scratches on the surface 4. Seamless when assembling the components |

|

| Bending forming: check whether the workpiece is consistent with the production drawing, and use hydraulic CNC bending machine to operate. Negative difference in size is within + -0.2mm, and negative difference in angle is within + -0.5mm. Features: the surface is not embossed, deformed and can not afford shadows, and the components are seamless, straight, and consistent with the hole position when assembled. |

|